Guy wire / stay wire supported masts

Subject list :

- Do you really need guy / stay wires?

- How many stay wire levels do you need?

- Three or four hook collar ?

- The awkward “off the wall” stay wire...

- The stay wire (what type of wire?)

- Tensioning the stay wires

- Attaching the wire to the tensioners

- How tight should the wires be?

- The anchors

- Getting the edifice up in the air...

- The (not that serious) test

- Links for purchasing the guy wiring hardware

Guy / stay wire supported masts, your aerial pole or a TV transmitter, exactly the same principle ! See ATV's aerial array and Ridge Hill transmitter (in the picture below). Actually, in one very important respect, they’re rather different. Most cable stayed transmitters are not firmly fixed at the bottom, they’re mounted on a ball (tubular masts like Winter Hill for instance, are not). Also, our install is actually “semi stayed”, this is because it was done in a bit of a rush (the wind was whipping the pole around like nobody’s business) which resulted in, to be frank, a bit of a bodge. We couldn’t be arsed to take the whole install down to get the hook collar at the top ! Note : standing on the chimney is not advisable….. We reckoned (correctly as it turned out) that supporting it half way up the pole would be sufficient. It should be borne in mind that this actually puts more strain on the wires and anchors due to the leverage effect of the unsupported length of pole above, but despite that (and the not recommended use of screw eyes as anchors ! ) it’s still there having been put up in 2001, having survived some vicious winds….

The first point to make in this article is are you sure you really need guy wires ? Two inch diameter poles, particularly the thicker 14 gauge/2.0mm type, really are quite strong and scaffold poles are even stronger. Here are some real world installations and our pole strength test results. The next point to (re)make is the weight of an aerial is almost irrelevant, it’s the wind loading which will break the pole, assuming it’s windy enough, obviously…… That’s where guy wiring an installation really does increase its strength, and, even more important for some installs (e.g. microwave transmitters and Starlink), it greatly reduces the movement in the antenna / dish. This was the biggest difference when we added stay wires to our install, it whipped about alarmingly in high winds before but with the wires on (even only supporting the mid point of the pole) it was far more stable. In fact an installation’s inherent resonance can contribute to its failure, this causes fatigue at its base where it is under most strain and where any installation will fail (if it ever fails). Adding stay wires can damp any resonance, though so can slightly altering the pole length or indeed rearranging the aerials on the mast.

Bearing in mind that it’s the unsupported length of the pole which is the crucial limiting factor to an installs’ strength / rigidity you can use that to work out how many stay wire levels you need. Remember that other than the topmost set of stays the intermediate ones are only there to compensate for the wind loading on the pole. So the question is if you have a 2” x 14gauge/2.0mm pole supported at both ends how far apart can the stay levels be ? I’d have thought it’d be quite a long way ! At least 20 ft, and possibly more (unless it’s a particularly exposed location) ? The picture above right is of Ridge Hill transmitter which has 4 stay levels, rather more than that required on the average aerial installation, I’d have thought.

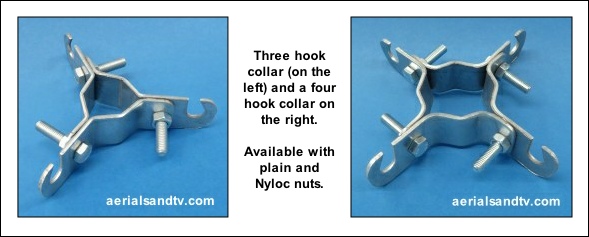

Three or four hook collar ?

Nearly all stay wired transmitter masts use a three hook collar with three stay wires spaced 120 degrees apart, as do most aerial installations. However, if the convenient points to mount the stay wire anchors just happen to be 90 degrees apart then we also sell 4 hook (as well as 3 hook) collars. But bear in mind that fitting 4 wire sets means 33% more components to buy and fit…..

It will be relatively rare to be in a position to fit the stays at exactly 120 (or 90) degrees, but what matters more is that they’re capable of providing support to the mast from whichever direction the wind blows. Installs using an “off the wall” stay wire should really use 4 sets of stays in order to minimise the sideways force on the guy wire’s lateral pole.

The stay wires are invariably attached to the pole using three and four hook collars.

Which wire to use ? Well pre galvanised seven strand catenary wire - 7 x 20 gauge/ 0.9mm strands - (sold here) is pretty universal, after all it has a 2000Kg (two ton) breaking strength !

On the question of what angle to incline the stay wires the flatter the angle the stronger the install will be, but the footprint of the install will be greater and you’ll use more wire ! Bearing in mind that the strength of the aforementioned catenary wire, I wouldn’t worry too much about what angle the wires will be at, within reason obviously. I’d aim for about 45 degrees, possibly down to 20 degrees for an “off the wall” stay wire.

How much wire will I need ? A bit of advice from our old mate Pythagoras is invaluable. As an example, on a pole 15m high, with anchor points 14m out from the base, the stay wires would be 20.5m ( = square root of 15 squared + 14 squared).

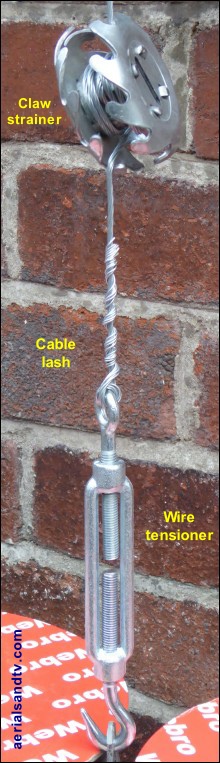

Tensioning the stay wires : almost all are by screw type wire tensioners (we sell the heavier duty M8 wire tensioners). “Claw tensioners” are available but rare. The latter have the advantage they can wind on far more cable, thus you don’t run the risk of running out of adjustment before the wire is tight enough. But on the other hand the way claw tensioners work means the cable is run over a relatively sharp metal edge which must weaken it, and more so over the years as the cable is rubbed slightly over the edge every time the wind blows ?

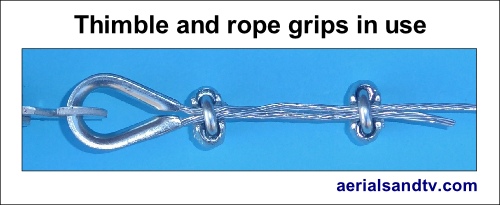

When it comes to installing the wires on the hook collars, tensioners and anchor points we do stock thimbles (sold here) and rope grips (sold here). I would say that the former are worth installing at the hook collar end because the hooks have relatively sharp edges, but I wouldn’t have thought they were necessary at the tensioners or the anchors (unless the latter have sharp edges). As for rope grips I’m not really convinced they’re necessary at all (on this kind of install) provided the wire is lashed off correctly i.e. like a chimney lash wire, used in the picture above (for instructions see point 3 in this article). When we tested some wire, a claw strainer and screw tensioner we lashed them all together using the aforementioned method and, far from any slippage, as the weight went on the lash tightened up still further. I admit we only tested them to 60Kg (the maximum we practically could) but it still proved the point as regards the lash.

Steel thimble : to lessen the stress on the wire as it passes over any sharp edge.

Rope grip : to clamp two ropes together, generally after it has been looped round something. Not sure how necessary they really are, see above.

So, how tight should the tensioners be ? Not that tight is my advice. Remember you’re only wanting to take movement out of the install. This is important ! Movement at collar height will produce uneven pulling on the stays and anchors increasing the likelihood of failure (for this same reason never only fit one stay wire.) I’d do up the tensioners till they just start pulling the pole over, then stop. Remember that unless the anchors are in an unusually inaccessible place you can always tighten them up a bit in the future if you find there’s excessive movement in the installation. It is recommended that the wire tension is rechecked regularly, particularly in the period immediately after installation and also after any gales.

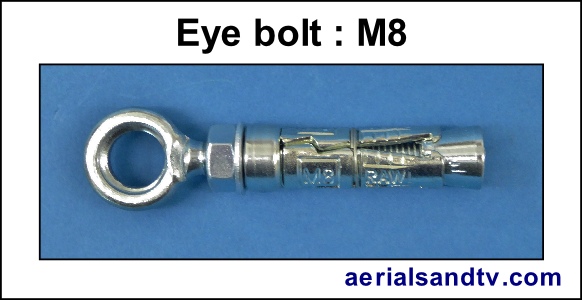

What about the anchors ? Obviously the stay wires are only as strong as the anchors they’re attached to, so it’s an important question. Most people just use shield anchor (“Rawlbolt” type) eye bolts into masonry (we sell an M8 eye bolt), but we also sell M10 J bolts and O bolts (usually supplied with our chimney lash kits but available separately by phone) which can be installed in steelwork or whatever. On the subject of eye bolts into masonry, it is preferable that wherever possible the load (of the cable) is applied sideways, or, at the very least, at an obtuse angle, not straight out of the wall. Anchors should be rechecked periodically, particularly after any gales.

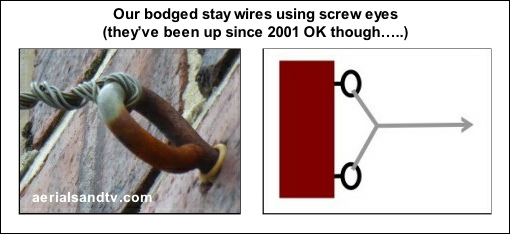

I do have an admission here, our aerial array uses our standard eye screws / wallplugs and with “sub optimal” catenary wire loading angles (see below for more on this)….. I’m not saying we’d normally recommend the use of eye screws for stayed installations but what can I say ? They've been there since Nov 2001 and they're still there now ! To be frank, so long as the cable is pulling at an obtuse angle to the bolt, it’d need a hell of a force to get it out, basically the eye bolt itself would have to bend and/or get pulled apart. Their big advantage is that you only need a 10mm drill bit (the M8 shield anchor version requires a 14mm hole), plus the fact installing them is less likely to crack the brick if excessive torque is applied.

Using eye screws is a bit naughty really, but they have been up since 2001, and they're still there now....

Note the zinc plated eye screw rusting….

Although not really recommended for catenary wire anchors we used screw eyes on our install because it was a rush job and we had them (and a 10mm drill bit ! ) in stock. Furthermore (although it’s not obvious from the picture) the catenary wire loading angle is only 45 degrees, and significantly less for one of them. But there haven’t been any problems since 2001 ! Actually, that’s not quite true, one of the screw eyes was installed in an adjacent chimney and the stone was a bit soft plus the eye was installed a bit too close to the edge so eventually this started cracking the stone. It never actually failed but it concerned me so I installed a second screw eye about a foot to one side, lashed a wire between them and then installed the tensioner to the mid point (see above picture). That spread the load and in addition meant that the loading angle on the eyes was about 45 degrees.

M8 eye bolts (sold here) are pretty heavy duty. The only problem is you need a 14mm drill bit and you’ve got to be careful not to crack the brick.

Below are three other methods of anchoring the catenary wire.

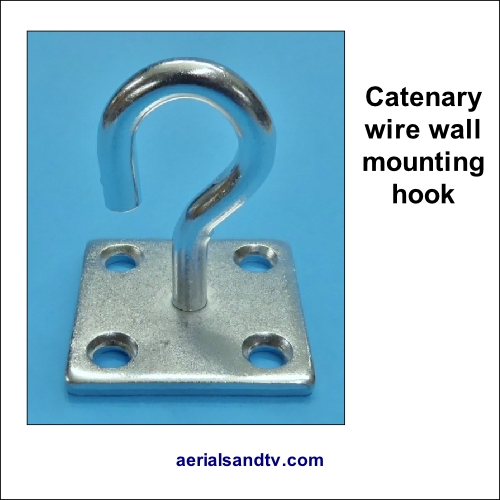

We have a wall mount catenary hook (sold here) capable of accepting four screws, bolts or wall anchors.

There are also O bolts (sold here) and a J bolts (sold here). These can be used in a variety of situations but commonly used to attach a catenary to a pole, as shown. Note that the pole would have to be very rigid as the loading would be sideways. This can be achieved by using a pole of large diameter with a decent thick wall thickness, or staywiring it !

How to get the edifice up there. See above for more detail about each part of the process. Obviously the installation must be done when there’s no wind ! The big problem is that once installed you can’t normally get to the hook collar, nor align the aerial by twisting the pole, not by more than a few degrees anyway. Thus you pre install the aerial (and cable) on the pole and make sure it’s pointing in the right direction relative to the stay wire anchors etc and keep it there as the installation is progressing ! First install the anchors. Next bolt the hook collar onto the pole (or what will be the top section of pole, most installs use pole sections joined with pole couplers (sold here) and install the stay wires. Now loosely tie off the stay wires to the anchors. Add extra lengths of pole as required at this point. If the pole is of unmanageable length (most will be ! ) the use of assistants holding the pole vertical by means of the [as yet unlashed stay wires] is to be recommended……. Install the pole on its brackets. Now add the wire tensioners and pull the stay wires as tight as possible before lashing off. Now tighten the stay wires with the tensioners.

It is a recommended that the tension on the stays is rechecked regularly, particularly a few weeks after installation and after any severs gale. Also ensure there are no resonance effects on the install, particularly if it’s a particularly tall pole. Moving the position of the collars may well be all that is necessary to eliminate any unwanted resonance in the pole.

Putting a bit of weight on…..

I had originally had some idea of testing stay wiring products to destruction, in particular I was interested to know how much the claw strainers reduced the wire’s load bearing ability. However, very quickly I realised that wasn’t going to happen, it just wasn’t practical…….. The maximum load we could apply was only 60Kg, whereas catenary breaking strain is 2000Kg ! Even if claw strainers reduced that by half it’d still be 1000Kg.

Anyway, it was still interesting to see how the claw strainers actually took the load, and it also (re) proved that a basic lashing kit lash really is slip proof.

The awkward “off the wall” stay wire…..

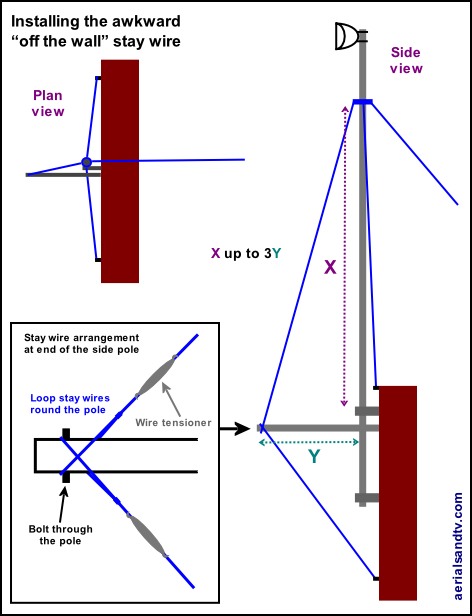

The easiest place to mount a pole is on a wall, but if the pole requires stay wires (either because it is particularly high or the antenna requires “minimal movement”, e.g. Starlink) where does the “off the wall” guy wire go ? If you own the building opposite that would help, but most people don’t…. There is, however, a solution which is illustrated in the picture below.

Worked example.

20ft main pole with 2ft bracket spacing (the pole is guy wire supported) gives 18ft of unsupported length above the top bracket. If the collar is 4ft from the top, the length above the top bracket to the collar (X) = 14ft.

Therefore Y should be at least 5ft.

If the main pole has a 6” standoff then the side pole should be about 5ft 6in, or longer, in the latter case the guy wire would be under less strain.

It is preferable to use 4 sets of stays (rather than 3) so as to minimise the sideways force on the lateral pole required for the “off the wall” stay, see “plan view” in the accompanying graphic.

Basically the horizontal pole is in compression and allows that stay wire to give support in an “off the wall” direction by redirecting the tension to an additional anchor point below the bottom bracket.

As a guide the main pole can be up to about three times of the length of the main (horizontal) side pole*. Bear in mind that the guy wire collar (on the main pole) does not have to be at the top, a 2 inch H/D (2.0mm wall) pole is very strong and rigid over shorter distances, a scaffold pole (4.0mm wall) even more so.

* Even if the side pole is less than a third of the main pole’s length (and the angle of the “off the wall” stay wire is thus steeper) it will still give support but, obviously, as the angle gets more acute the degree of support will reduce.

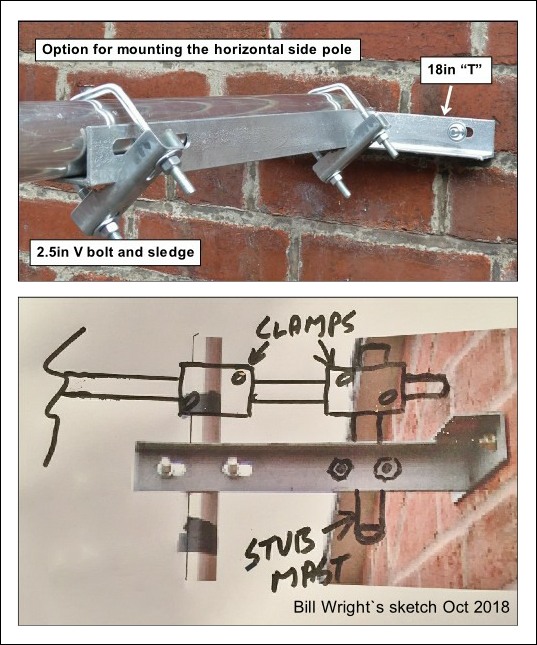

A couple of examples of side pole mounting installations :

Sales links for the guy wiring hardware :

Hook collars

Catenary wire

Wire tensioners

Thimbles

Rope grips

Eye bolts.

[link]